Smoke suppressant TC-1026

Keywords:

Smoke suppressant TC-1026

Hotline:

相关内容

Classification:

- Description

-

- 商品名称: Smoke suppressant TC-1026

Smoke suppressant TC-1026

一、Products

1.Burning smoke and hazards

Heavy fuel oil type gas turbines are used for power generation, as well as industrial furnaces, boilers, etc. Its main fuel is relatively economical heavy fuel oil, which is the residual heavy residual after petroleum refining, with high viscosity, high boiling point and poor volatility, and contains ash impurities such as S, Pb, K, Na, Ca, Mg, Fe, V, Ni, Zn, Al, etc. When burning heavy oil, it produces many negative effects, such as In order to solve these problems, one is to start from the structure of heavy oil combustion equipment and combustion process, try to make the fuel get filtered and clean, fully atomized, control the appropriate air to material ratio, provide good combustion conditions, the second is to start from the perspective of chemical additives, change the fuel The second is from the perspective of chemical additives, changing the chemical structure and physical form of the fuel, changing the chemical reaction process and the way of fuel combustion, so as to improve the combustion conditions and reduce the negative impact of combustion. Heavy oil combustion black smoke is the cause of incomplete combustion, the development of chemical additives is also based on the cause of the start.

The nature of the fuel fundamentally affects the generation of atmospheric pollutants emissions, heavy oil is a liquid petroleum fuel, 80-90% of the sulfur in crude oil remains in the heavy oil, almost all metal elements and mechanical impurities remain in the heavy oil, accompanied by the presence of asphaltene, gum, wax and other highly viscous substances, the presence of these substances determine the hazardous nature of heavy oil combustion, combustion is a rapid oxidation process of combustible mixtures, and accompanied by The products of complete combustion of fossil fuels are CO2 and water vapor; incomplete combustion process will produce black smoke, CO and other partial oxidation products, if the fuel contains S, N will generate SO2 and NOx, where NOx has N from the fuel (fuel type NOx) and N from the air (thermal type NOx) The conditions for complete combustion of fuel are the right amount of air, sufficient temperature, necessary combustion time, and adequate mixing of fuel and air, where adequate mixing of fuel and oxygen in the air is the basic condition for effective combustion, and the four factors to achieve effective combustion in the lowest atmospheric dirt emission conditions are air to fuel ratio, temperature, time, and turbulence.

If the amount of non-theoretical air, there is incomplete combustion, there are CO, CH compounds in the flue gas, plus N in the fuel is oxidized to NOX, high temperature combustion in the air will also be partially converted to NOX, these incomplete combustion products with SO2, SO3 together constitute a harmful component of the flue gas, not only pollute the atmosphere, but also cause the loss of calorific value.

TC-1026 smoke suppressant is a kind of fuel to change the physical form, promote the oxygen in the air and combustion reaction process, reduce the generation of harmful components in combustion and improve the cleanliness of the flue gas emissions. TC-1026 smoke suppressant consists of various functional components, there are oil sludge dispersant, oil droplet micro-explosion accelerator, accelerator, secondary combustion catalyst, cleaning agent.

Society's requirements for environmental protection are getting higher and higher, and the quality control of flue gas emission is getting stricter and stricter, the use of poor quality fuel affects the quality of flue gas emission even more, and the poor quality fuel has obvious black smoke emission. The use of special equipment to solve the smoke emission problem is not only expensive, but also increases a lot of management and maintenance costs, so the use of additives without condensation is a fast and effective measure.

After using TC-1026, it can reduce the deposits in the oil circuit and combustion, reduce the combustion coke, reduce the local overheating caused by combustion and high temperature oxidation for the combustion engine, reduce the damage to the equipment, reduce maintenance costs and improve operating efficiency.

2.TC—1026Smoke suppressant action and mechanism

①Stabilization and dispersion of sludge. As the unsaturated sites of asphaltenes in fuel are modified by compounds with one or more oxygen or sulfur atoms in the molecule, and gel condensates and complexes are formed, these condensates or chemical complexes are known as sludge, which hinders the injection of fuel and makes the supply of fuel oil to the combustion chamber unstable and unstable, while the sludge itself is poorly combustible and produces soot or polycyclic organic acids. Since sludge is mostly formed by the reaction of asphaltenes with oxygen in the air, the amount of soot formed by sludge can be reduced by preventing the accumulation of sludge by inhibiting oxidation or redispersing the formed sludge. tc-1026 focuses on the sludge dispersing effect according to the application object.

②The micro-bursting agent in TC-1026 is a two-component, two-step process to complete the deep atomization of oil droplets, in order to improve combustion efficiency and reduce pollutant emissions, the formation of atomized oil droplets need to be as small as possible particle size, and the modification of the mechanical structure of the combustion furnace is difficult to reduce the particle size of oil droplets to less than 100 microns Such small droplet sizes are dependent on the inherent physical properties of the fuel oil, many of which are relevant to controlling the size of the atomized droplets. The viscosity and surface tension of fuel oil are the most important influencing factors, and the functional component one of TC-1026 smoke suppressant can reduce the viscosity and surface tension of heavy fuel oil and promote the first atomization in the fuel nozzle. In the combustion process of atomized oil droplets, its diffusion rate is lower than its volatilization rate on the surface of oil droplets, so that in the flame area, the surface of oil droplets is hardened at the initial stage of volatilization, which leads to the volatile components volatilizing internally, and the internal volatilization leads to the bursting of fine oil droplets into ultra-fine oil droplets, thus greatly increasing the total surface area of combustion and promoting the complete combustion of fuel oil.

③The combustion aid changes the form of oxygen involved in combustion and accelerates the atomization process. the combustion aid component in TC-1026 provides the right amount of molecular oxygen for combustion, and when oxygen is provided to the oil droplets from outside in the form of air, the rate of oxygen consumption is greater than the rate of oxygen diffusion, making the oxygen concentration at the interface where combustion occurs very low, with the result that the total combustion rate is mainly controlled by the combustion of the substances involved in the molecular transfer rate rather than oxidation rate to control, while the addition of additives, not only reduces the viscosity of the fuel, but also due to the introduction of a high content of molecular oxygen, involved in the combustion of atomized oil droplets, the result makes the interface contraction very fast, thus quickly reducing the radius of the occurrence of combustion oil droplets, to play the role of deep atomization.

④Secondary combustion stage catalytic combustion, so that soot material outside the flame area into carbon dioxide, TC-1026 secondary combustion catalyst for organic metal compounds, can catalyze the secondary combustion of unburned carbonaceous material. The mechanism of action is that the organometallic compound can decompose active metal ions when burning with fuel, and the active metal ions can react with oxygen in the air to produce active molecules, which is a combustion catalyst for various fuels, and catalyze the secondary combustion of soot and polycyclic organic substances formed during the primary combustion of fuel droplets. The organometallic compound has a lubricating effect at high temperatures and increases the fluidity of the fuel.

3.TC—1026Smoke suppressant efficacy

①Save fuel. (about 0.5-5%)

②Reduces exhaust pollutant emissions, reduces smoke by about 30%-50% and carbon monoxide by about 50%-70%.

③It has the effect of cleaning, reducing carbon accumulation and cleaning the oil circuit.

④It has anti-corrosion effect and prolongs mechanical life.

⑤ Loosen combustion scale and improve the efficiency of burner.

⑥The main ingredient of this product is biological agent, non-toxic, harmless, biodegradable and environment-friendly.

二、TC—1026Application methods and precautions

①Used in kilns, boilers, heating furnaces, generators, etc. that use heavy oil as fuel.

②Adding quantity, depending on the oil quality: 500-1000ppm. the best adding quantity should be adjusted according to the blackness of the smoke.

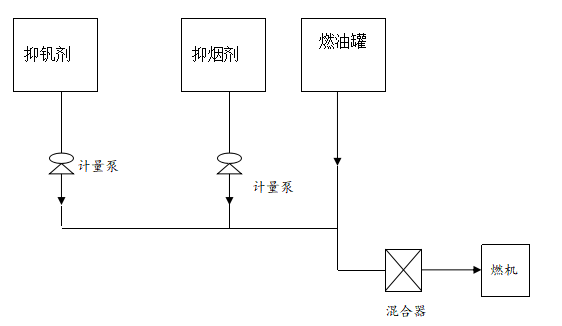

③For gas turbine generator set, set a dosing device near the Vanadium inhibitor adding port, add TC-1026 into the Vanadium inhibitor outlet line with Vanadium inhibitor through metering pump and enter the heavy oil together with Vanadium inhibitor or choose to inject before entering the oil line with mixing function on the combustion engine. Injected before the mixing function of the equipment on the pre-fuel line to ensure full mixing with the fuel. The amount of smoke inhibitor added should be individually adjustable according to the oil quality and smoke generation condition.

④When used in other combustion furnaces, the smoke suppressant can be pre-mixed with fuel oil in advance, or used with reference to the above methods of combustion engines.

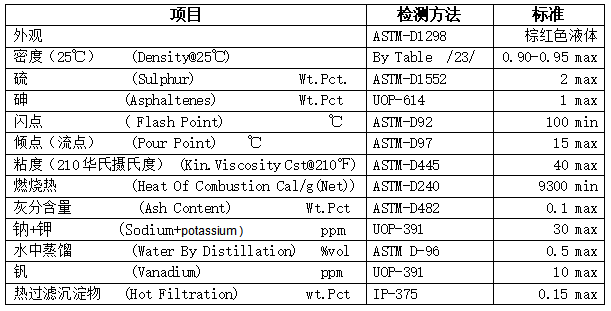

三、TC—1026Physical and chemical properties

四、TC—1026Packaging, storage and transportation

①Packaged in 200L iron drums;

②No dropping or pounding, keep away from open flame, store in a cool and ventilated place;

③Non-toxic, but contact with human skin is prohibited;

④Prohibit water or other materials to enter the packaging materials, shelf life of two years.

Related products

Online message

We will contact you within one working day. Please pay attention to your email.