Ultra-fine compound sodium bicarbonate desulfurizer

Keywords:

Ultra-fine compound sodium bicarbonate desulfurizer

Hotline:

相关内容

Classification:

- Description

-

- 商品名称: Ultra-fine compound sodium bicarbonate desulfurizer

Background: Development of sodium bicarbonate dry desulfurization technology

In many industries, such as coking, sintering, refractory, etc., the dry desulfurization process has superior industry adaptability. It is reflected in non-corrosive, no waste water, low temperature drop of flue gas and effective removal of SO3.

The gas-solid reaction characteristics of dry desulfurization, to achieve more stringent emission targets, the reaction activity of the desulfurizer itself, there must be higher requirements.

With China's ultra-low emission requirements for various industries, sodium bicarbonate dry desulfurization process, as the most efficient dry desulfurization process, is generally accepted by various industries, promoting the widespread use of sodium bicarbonate dry desulfurization process.

The most efficient dry desulfurization agent: sodium bicarbonate

The most reactive alkali metal on the periodic table of elements

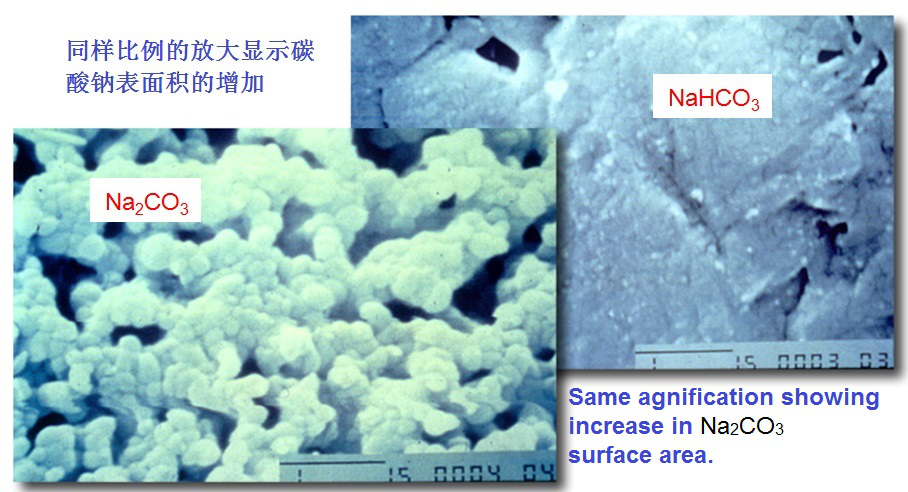

Surface change under high temperature calcination conditions, the reaction interface increases significantly

Optimal calcination reaction temperature conditions: 120~180 ℃

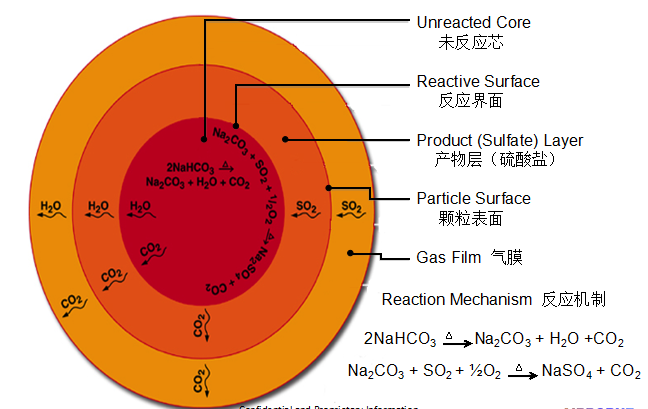

Sodium bicarbonate desulfurization reaction mechanism

Calcined surface modification of sodium bicarbonate

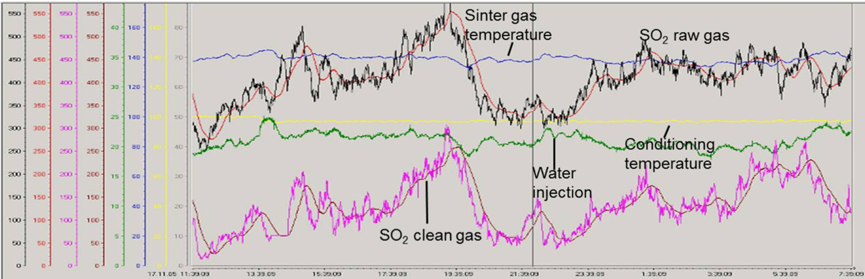

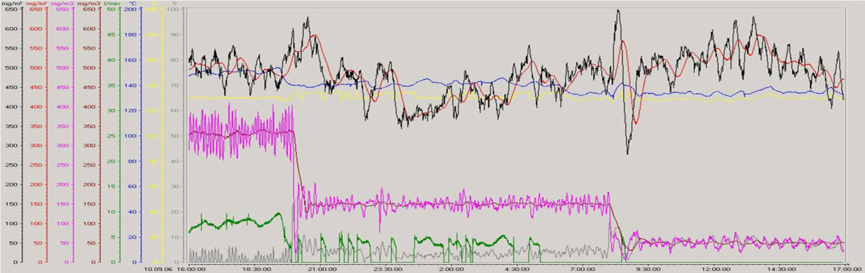

Comparison of actual operation of sodium-based-calcium-based desulfurizers in the same unit

Actual operating data of 1 million cubic meters of sintered flue gas desulfurization at voestalpine Linz Steel Plant

When using the desulfurizer CaOH, the net flue gas SO2 content (red line) fluctuates with the original flue gas SO2 content (black line) due to the limited calcium reactivity.

The net flue gas SO2 content (red line) fluctuates with the original flue gas SO2 content (black line)

Courtesy of Austrian Steel Associates

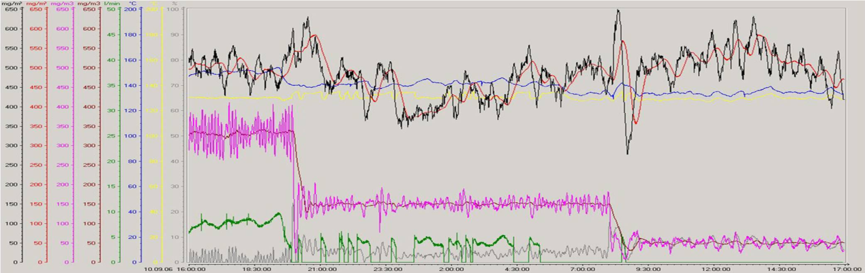

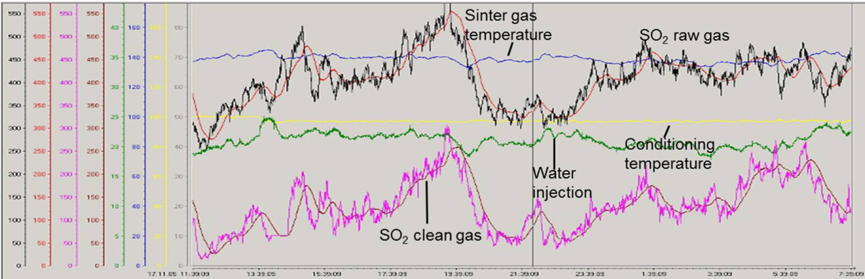

Comparison of actual operating data of sodium-based-calcium-based desulfurizers in the same unit

Actual operating data of the 1 million cubic meter sinter flue gas desulfurization at voestalpine Linz Steel Plant

When using the desulfurization agent NaHCO3, the extremely high reactivity of sodium ions

The net flue gas SO2 content (red line) is not affected by the fluctuation of the original flue gas SO2 content (black line) and can be steadily controlled at the emission level set by the system.

Courtesy of Austrian Steel Associates

Courtesy of Austrian Steel AssociatesComparison of sodium-calcium desulfurization operation

Sodium-based desulfurizing agent

Calcium-based desulfurizer

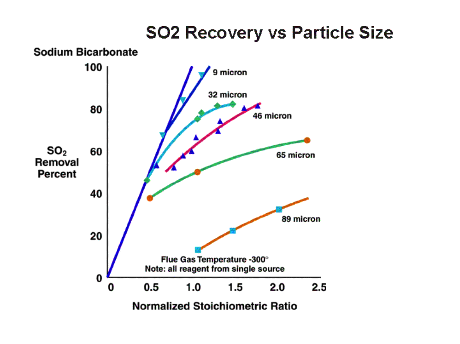

The relationship between desulfurization efficiency and sodium bicarbonate particle size

Sodium bicarbonate dry desulfurization

The relationship between desulfurization rate and sodium bicarbonate particle size

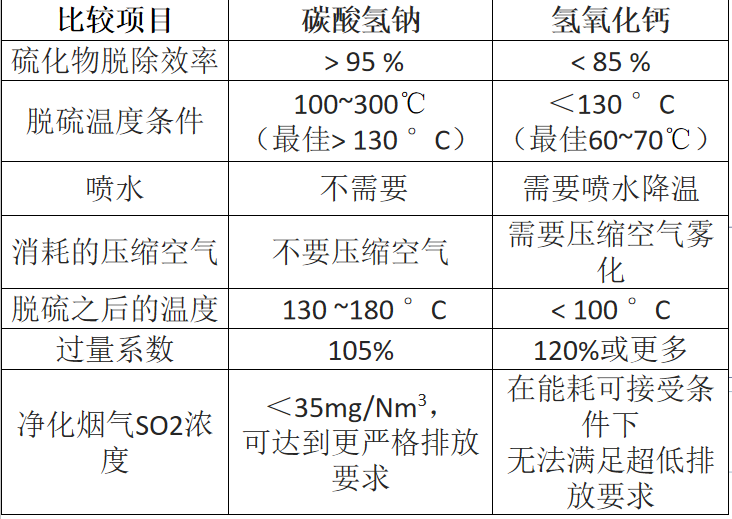

Comparison of different desulfurization agents for dry desulfurization

Problems of existing domestic sodium bicarbonate desulfurizer

Contains 8~12% sodium carbonate, Solvay and Japanese products only 2~4%

The particle size is too large, need to invest in equipment processing and grinding, increase the cost

Excess coefficient of desulfurization of unground sodium bicarbonate is over 120%.

Sodium bicarbonate itself is expensive

Foreign high-quality sodium bicarbonate products are sold at more than 3000 RMB/ton

Domestic sodium bicarbonate price: 1800 yuan / ton (200 mesh, general industrial products)

2500 RMB/ton (500~600 mesh, superfine products)

3000 yuan / ton (800 ~ 1200 mesh, ultra-fine products)

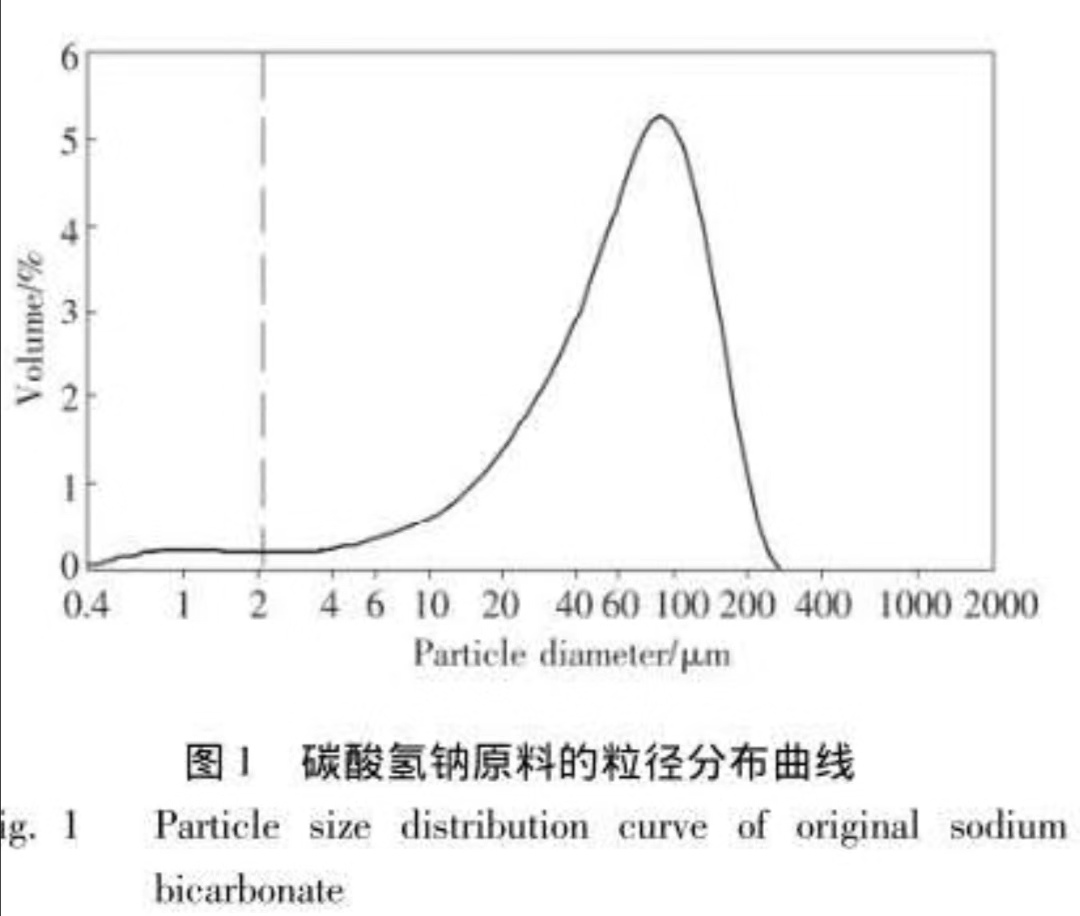

Industrial sodium bicarbonate particle size and distribution

Cannot meet the particle size requirements of dry desulfurization

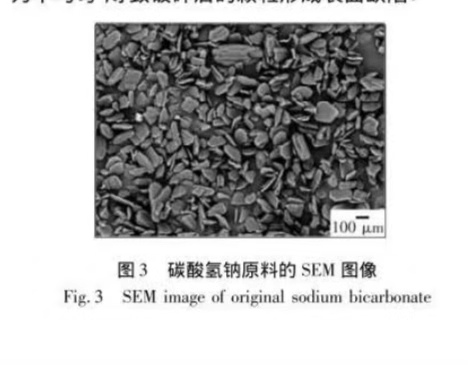

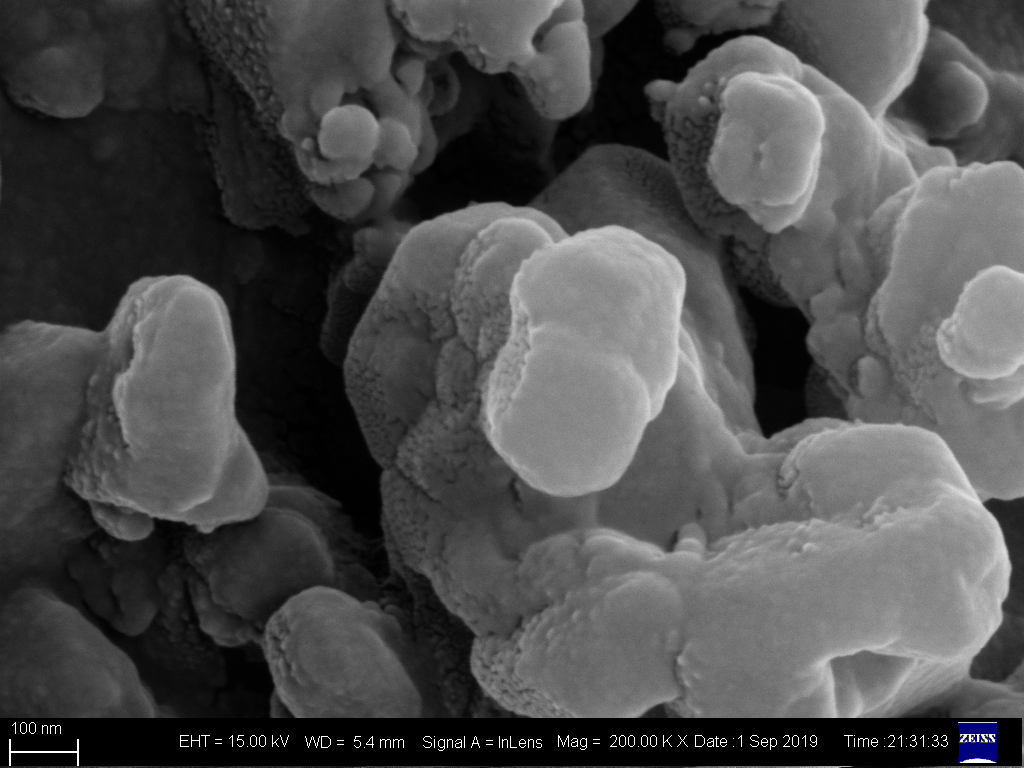

Electron micrograph of industrial sodium bicarbonate product: low desulfurization efficiency of lamellar structure

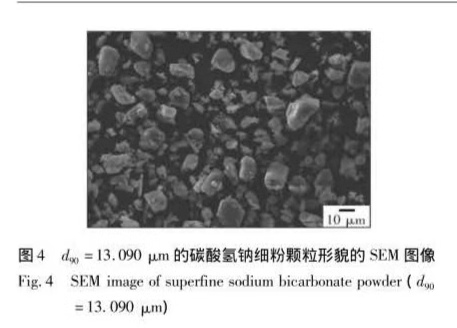

Milled and processed sodium bicarbonate: grinding cost 150~300 RMB/ton

Ultra-fine modified sodium bicarbonate desulfurizer

For the traditional sodium bicarbonate desulfurization agent in the dry desulfurization existing high grinding energy consumption, low reaction utilization rate, strict flue gas temperature requirements, high cost problems, the use of innovative processing technology to modify the processing of sodium bicarbonate desulfurization agent, and the addition of anti-agglomeration and efficiency components, the development and production of dry desulfurization special ultra-fine modified sodium bicarbonate desulfurization agent, directly for dry powder injection desulfurization.

Product features:

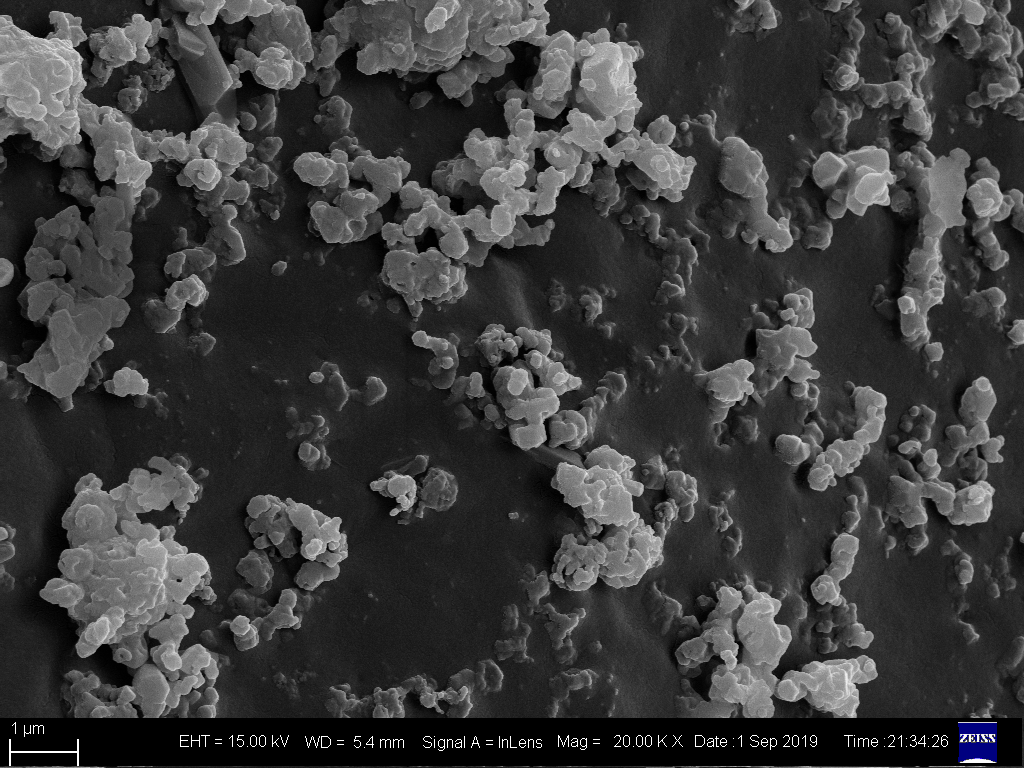

With special sub-micron surface structure, equivalent to 10,000 mesh fineness, extremely high desulfurization efficiency, can steadily reach and flexibly regulate the emission index.

Direct use, no need for mill system pre-grinding, saving energy costs and labor.

Reduce the flue gas temperature requirement of dry desulfurization, can be applied to low temperature flue gas below 100℃, wider application range of desulfurizing agent, save the cost of flue gas heating, do not worry about the effect of flue gas temperature fluctuation on desulfurization effect.

Improve the utilization rate of desulfurization agent and reduce the excess coefficient by 5~10%.

Compared with the direct use of sodium bicarbonate for dry desulfurization, the cost of desulfurization agent is reduced by 20 to 30%.

Ultra-fine modified sodium bicarbonate desulfurization agent-surface form

Ultra-fine modified sodium bicarbonate desulfurizer-submicron structure

THANKS FOR YOUR WATCHING

Ultra-fine modified sodium-based dry desulfurization agent, replacing sodium bicarbonate, to achieve high-efficiency dry desulfurization, reducing the cost of desulfurizer by 20 to 30%.

Pre:

Related products

Online message

We will contact you within one working day. Please pay attention to your email.