相关内容

Classification:

- Description

-

- 商品名称: Sterilizing agent

TC-001

(Oil-field biocide-algaecide)Introduction

1.The limitations of the biocide-algaecide of modern petroleum industry

Different types of water systems are used during the process of petroleum industrial production, such as the water used for oil well, circulating water, cooling water and so on. For ensuring the normal operation of industrial production, germicidal and algicidal treatments must be carried for these water systems. But current petroleum industry still makes mistakes on the choosing and using of water-treatment agents, main problems include:

1) The chosen germicide is inapplicable for the petroleum industry, which the type of compound can rapidly decompose the effective ingredient of the germicide. Therefore, the choice of a suitable germicide is important.

2) The thalli has produced drug resistance. Because of the long-term use of one type of germicide, the microorganism has produced drug resistance. Therefore, the initial dosage cannot provide an ideal effect. The dosage is usually increased for achieving the expected performance, which would increase the cost and waste.

3) The applied range of germicide is not widespread. Some germicides have inefficient performance to the main thallus of the petroleum industry, which cannot effectively control the rust fungus, SRBs, anaerobe, legionella and so on.

Because of the reasons stated above, a right selection of biocide-algaecide is required for the water-treatment of petrochemical industry to ensure the normal operation of production and save the cost.

2.The status of microorganism of petrochemical industry

Water is the most-use heat conductor and transmission medium. Because water body contains different additives and other nutrients or the water body has been polluted by organics, which provide an ideal environment for the growth and reproduction of microorganism. If the microorganism cannot be efficiently controlled, the high reproduction of microorganism will produce slime which will aggregate at the productive pipeline or somewhere of the equipment to form a scale layer, hence the efficiency of heat conduction and mass transfer will decrease. On the other hand, anaerobe can breed inside the slime and produce hydrogen sulfide which will cause serious corrosion to the equipment and also release toxic gas. Hence, the equipment and pipeline need to be changed frequently and the production is influenced.

Another important reason for water-treatment in petroleum industry is the circulating water and cooling water of oil-field contain numerous legionella, which will diffuse into air and cause serious risk to human health. Therefore, for ensuring the normal production of petroleum industry and the safety of workers, any systems involved in petroleum industry should have sufficient treatment of sterilization.

3.The development of biocide-algaecide for water treatment of petroleum industry

Water resource is gradually reduced and the ecological environment is gradually deteriorated with the fast development of industry, the protection and recycle of water resource is highly important, and the requirement of sterilization for water-treatment is higher and higher. The water-treatment agent is developed as more efficient, more widespread and lower toxicity.

There are limitations exist in current widely-used biocide-algaecide, which cannot satisfy the requirements of petroleum industry. The utilize of new antiseptic agents and complex germicides are more and more important.

The most-use biocide-algaecide is isothiazolinone in petroleum industry. There are also other good germicidal agents, such as glutaraldehyde, DBNPA, bronopol and so on. However, since the price is expensive and the application range is not widespread, these germicidal agents are gradually lost the place of sterilization for petroleum.

The germicides of quaternary ammonium salts is very effective to algae, but the applicable range for bacteria is not wide enough and the effect on SBR is very poor. Therefore, they are not suitable for petroleum industry.

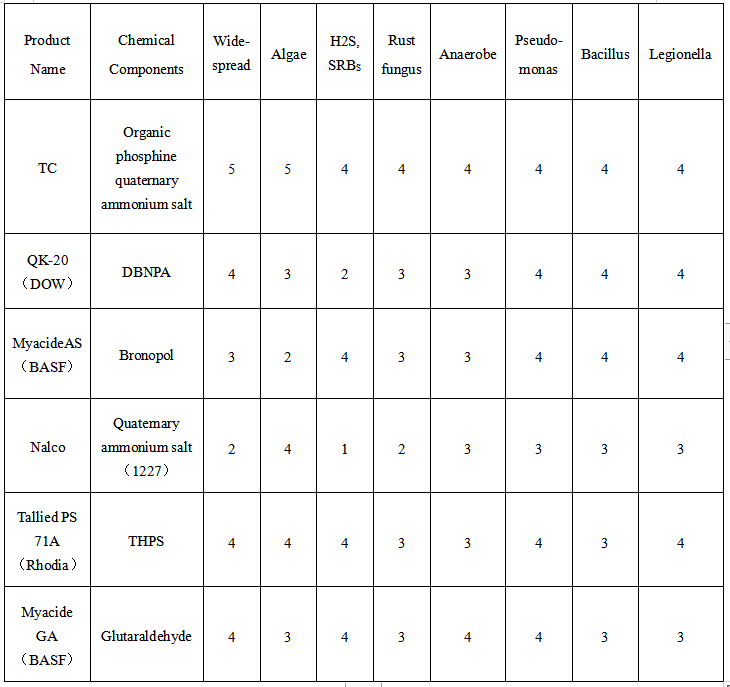

The products of FOSHAN TIANCHEN combine the features of different germicidal agents and have increased range of application, which overcome the problem of insufficiency of single germicide and reduce the dosage amount. They ensure the efficiency of sterilization and also save the cost.The performance on controlling the thallus of oil-field with using different germicidal agents. (5: best performance, 0: non-available)

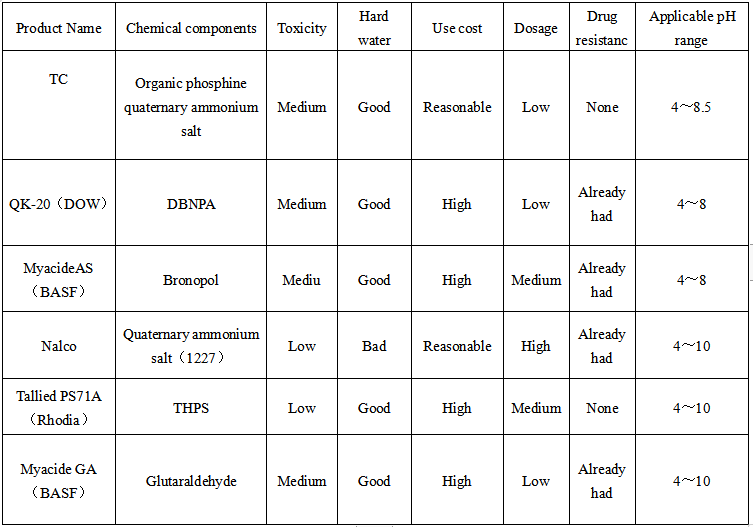

The range of application and notifications of the germicide for the water-treatment of oil-field.

Features of biocide-algaecide of TC-series:

1.Fast and long-acting sterilization, wide range of applicable pH.

2.Better performance than any single-use biocide-algaecide, more widespread, has special effects on rust fungus, H2S, anaerobe, legionella and algae which are common in petroleum industry.

3.Low toxicity, easy operation.

4.Green products which can degrade automatically after use, can be emitted directly without the environmental contamination.

5.Good compatibility with other oxidation-type and nonoxidation-type germicides, not influenced by hard water.

II. The working mechanism of biocide-algaecide of TC-series

There are several working mechanisms for biocide-algaecide, mainly the permeation into the cell of thalli and the combination with amino group and sulfur group inside the cell which prevent the normal cellular metabolism, hence prevent the normal cellular growth and reproduction to achieve the sterilization and algae removal.

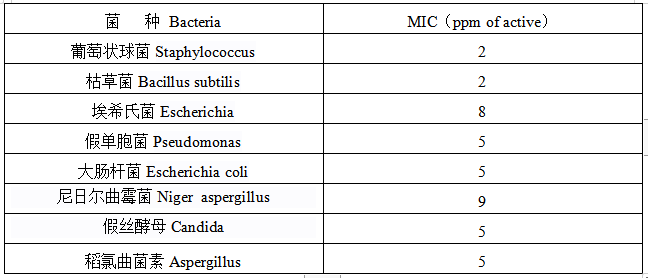

III、The sterilization effect of the biocide-algaecide of TC-series. (minimum inhibitory concentration, MIC)

TC-series biocide-algaecide is also very effective to legionella as all legionella with a concentration of 50 ppm can be killed in one hour, and it is also very effective to algae at the same time. TC-series biocide-algaecide has better effect as the temperature is higher. TC-series biocide-algaecide has rapid and long-acting effect on sterilization and algae removal under the condition of pH 4~8. Therefore, TC-series biocide-algaecide is the best choice of biocide-algaecide for injection water of petroleum industry.

四、IV. Dosage of TC-series biocide-algaecide.

The dosage of product depends on the temperature, water components and the pollution level of microorganism. Generally, the maximum dosage is recommended for summer and for heavy pollution, the minimum dosage can be applied in winter. If the water contains numerous thalli, and there is biogenic deposit on the surface of equipment and the interior of pipeline, two- times of maximum dosage is required and last for one month to clean up the slime and organisms of the system. See the dosage in the table below:

Next:

Related products

Online message

We will contact you within one working day. Please pay attention to your email.