Anodic oxidation wastewater treatment technology

The vast majority of anodized aluminum products must be chemically polished, referred to as chemical polishing.

Keywords:

Anodic oxidation wastewater treatment technology

Hotline:

相关内容

Classification:

- Description

-

- 商品名称: Anodic oxidation wastewater treatment technology

The vast majority of anodized aluminum products must be chemically polished, referred to as chemical polishing.

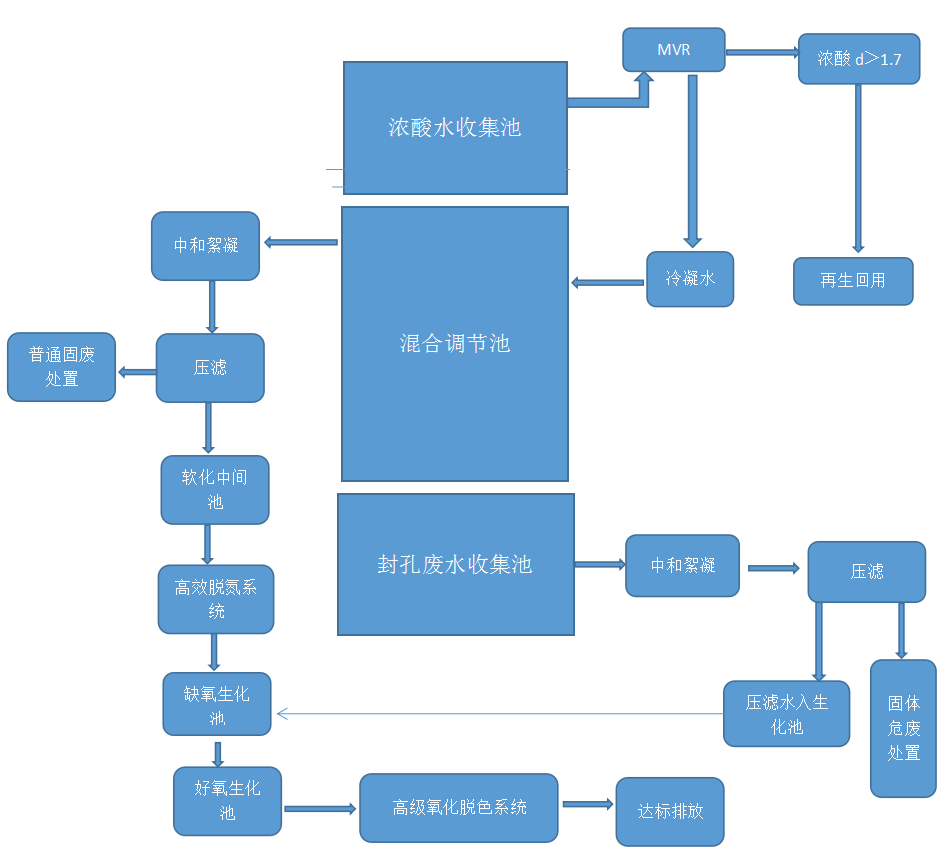

The vast majority of anodized aluminum products must be chemically polished, referred to as chemical polishing. The current chemical polishing process must use 2 acid or 3 acid (sulfuric acid, phosphoric acid, nitric acid) I found through investigation, in the process of acid polishing production, heating consumption and chemical polishing products consume a small amount of acid, about 30%, while a large amount of acid is brought out of the acid tank through the surface of the product and into the wash tank, due to the viscosity of the acid is very large, bringing out the acid up to 70% or more, these are brought out in large quantities The composition and chemical properties of the acid brought out of the acid tank are the same as those of the original acid tank, only diluted by water. Therefore, the recovered acid can be reused if the recovery process is appropriate. Through the recycling equipment, the waste acid water is filled and processed into acid that can be used again, and the water in the waste acid water is evaporated at low temperature under negative pressure and condensed into water that can be returned to the washing and filling tank for further use, or discharged directly if it is not to be used. Not only the waste to treasure can be deeply supported by the state, but also in line with the current environmental protection department of phosphorus-free and zero sewage disposal requirements.

Related products

Online message

We will contact you within one working day. Please pay attention to your email.