Electroplating wastewater treatment technology

The wastewater containing copper, nickel and cyanide from the production process is all remitted to the comprehensive conditioning tank and sent to the primary cyanide-breaking oxidation tank through the lifting pump 1, where the CN- oxidation is mostly removed by the oxidation of active chlorine, and the effluent flows into the intermediate tank 1 since.

Keywords:

Electroplating wastewater treatment technology

Hotline:

相关内容

Classification:

- Description

-

- 商品名称: Electroplating wastewater treatment technology

The wastewater containing copper, nickel and cyanide from the production process is all remitted to the comprehensive conditioning tank and sent to the primary cyanide-breaking oxidation tank through the lifting pump 1, where the CN- oxidation is mostly removed by the oxidation of active chlorine, and the effluent flows into the intermediate tank 1 since.

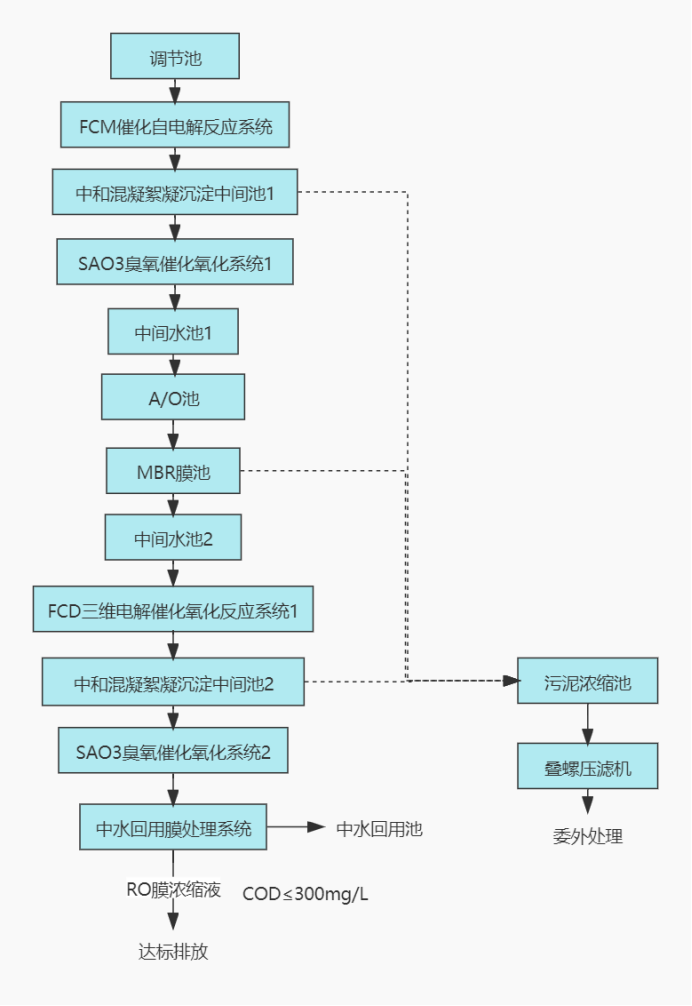

The wastewater containing copper, nickel and cyanide from the production process is all fed into the comprehensive conditioning tank and sent to the primary cyanide-breaking oxidation tank by lifting pump 1, where most of the CN- oxidation is removed by the oxidation of active chlorine, and the effluent flows into the intermediate tank 1.

The wastewater from the intermediate pool 1 is acid-adjusted to a pH of about 3.0 to 4.0, and is lifted and sent to the FCM-IV catalytic self-electrolysis reactor via pump 2 for oxidation-reduction reaction; the effluent flows to the time-delayed aeration neutralization coagulation sedimentation tank, where the pH is adjusted to about 8--9 by adding alkali, and then it is mixed-flocculation-sedimentation to realize mud-water separation; the supernatant after sedimentation flows to the AO anoxic aerobic biochemical reaction system to further remove CO The supernatant after sedimentation flows to the AO anoxic aerobic biochemical reaction system to further remove the COD in the water; the effluent from the secondary sedimentation tank of the biochemical system is introduced into the intermediate pool 2.

The wastewater from the intermediate tank 2 is then sent to the SAO3 ozone catalytic oxidation reactor through the lift pump 3 to further degrade the residual organic matter in the wastewater; finally, the wastewater flows into the designated clear water tank and is discharged or reused after the water quality indexes are tested and passed.

The small amount of sludge generated during the treatment of delayed aeration neutralization coagulation and sedimentation and AO biochemical system is thickened and treated by the existing hazardous waste center of Fujing Electronics, and the mud cake is shipped out after sludge dewatering, and the clear liquid is returned to the comprehensive adjustment tank.

Related products

Online message

We will contact you within one working day. Please pay attention to your email.